This will allow you to make more tenacious engines

Researchers from Tohoku University (Japan) have developed an analysis method to predict the degree of engine wear and scoring. Using it, you can increase the life of the components of any equipment.

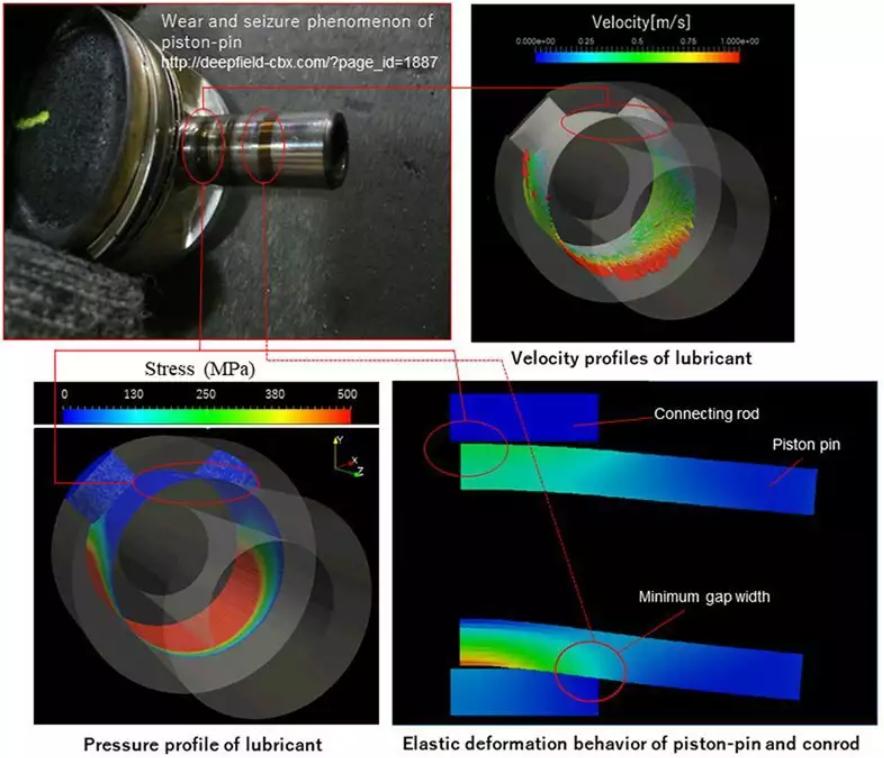

Reciprocating engines use reciprocating motion to convert combustion energy. The most serious breakdowns in such motors occur when the oil film on the surface breaks. This leads to increased friction of parts, rapid wear and even scuffing.

Piston pins and connecting rods need constant lubrication while in motion. However, to verify the effectiveness of the lubrication and determine the degree of wear, long-term endurance tests are necessary. Forecasting and calculation of wear without tests were still considered impossible.

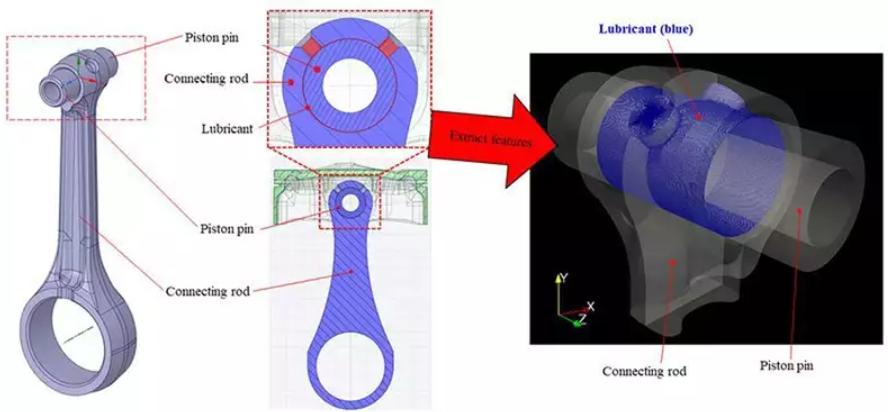

But a group of scientists from the Institute of Fluid Dynamics of Tohoku University led by Professor Jun Ishimoto and Honda Motor Co., Ltd. developed a special multi-phase analysis method.

They not only modeled and predicted tribological properties (a branch of physics about the contact interaction of solids during their relative movement), but also determined the degree of arcuate deformation of the piston pin as the cause of connecting rod seizing.

“With this predictive method, it will be easier to prevent unnecessary damage in automotive engines and other industrial equipment,” Ishimoto said.